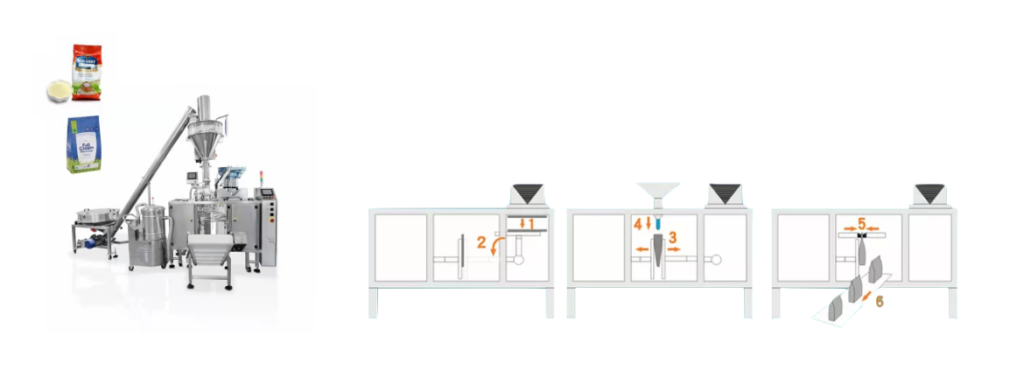

What is MINI Doypack Machine

MINI DOYPACK Machine for Pre-Made Pouch. It can be your current or maybe future needs! And if you still don’t know what it is and how it’ll make the work done for you,Please don’t rush to make a decision. Stop and take a few minutes to quickly scan the following articles. You’ll get twice the result with half the effort.

The functions of the MINI Doy Bag packing system is mainly help you feeding, weighing,dosing and sealing pouch automatically. It’s flexible to cooperated with all types of Dosing device and complete all your individual requirements!

Machine Feature

* SS304 Main machine Frame & material contact part SS304

* Overall Speed: Just 5~15bags per min, relatively slow

* Application: Multiple Pre-made Pouch Formats

* MINI Design, Small Space Occupied

* One Working Position

* Low Operation & Maintenance Cost

* Fully Automatically:

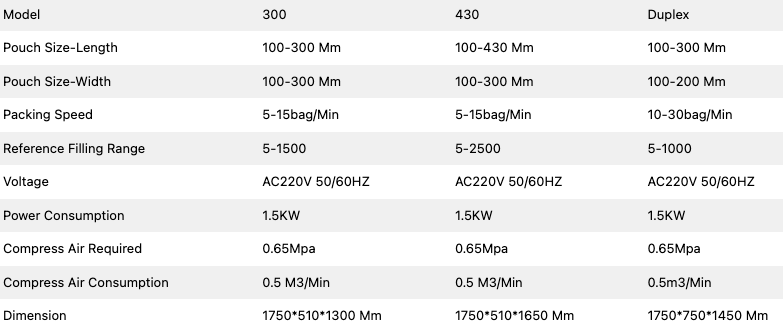

Basic Parameter

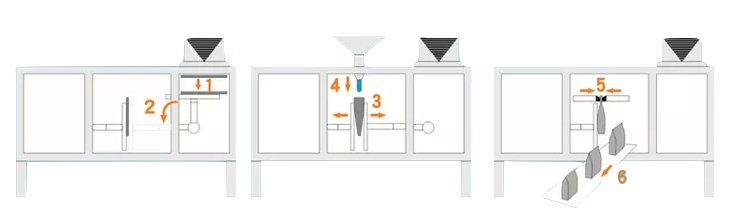

Main Working Flow:

Pickup Pouch →Bag opening → Date Printing(Option) → Zipper Open (Option) → Filling (by Dosing Device) → Bag Sealing → Finished Bag Output

The MINI Doypack Machine can be suitable for all kinds of premade Pouch, include but no limited to stand up Pouch with or without Zipper, side sealing Bag, Premade Pouch with Spout etc. Sample finished bag as below:

You may ask, what exact products this machine can this handle, and how to be implemented?

Common used sector for the Mini doypack machine

For Granular –Dosing system could use multihead weigher or Linear Weigher

Generally, 10-heads weigher is enough for handling general granular, like sugar, rice, nuts, peanuts, chips, etc. It can ensure pretty high accuracy with tolerance around ±1~3g per bag. And weighing speed can be 10~60 bags per min.

If you have really limited budget and want to spent less amount fund on beginning the project, 2 heads or 4 heads linear weigher will be another great backup dosing plan that worth considering. It’s slightly less accurate, and speed is slower than combination weigher, but totally enough to match with MIN Doypack machine and get total production capacity at 5~15bags per min.

For Liquid –You’ll need to adopt Piston Liquid Pump as Dosing System

The piston liquid pump can measuring different types of liquid, no matter free flow liquid like water, milk, honey, wine, or sticky liquid such as honey, chilli sauce, tomato paste, mayonnaise sauce, shampoo, etc. You could use one liquid Pump for dosing different bag capacity, it’s super simple adjust by one handle.

For Powder –You should equipped with Auger Filler Weighing

The Auger Filler is perfect dosing device for weighing powder. Include but not limited to milk powder, protein powder, flour, seasoning powder, rice powder, checical powder, coffee powder, soy powder etc.

The auger filler is servo motor control, and has one measuring screw inside the filler to measuring powder in high accuracy. By change the measuring screw, you could easily change your bag capacity. You can also add vacuum cleaner to collect dust if your powder is easy raising dust type.

In a word, if you are trying to start new business with low amount, and the daily production need is not very big for testing high-end Market. Then the MINI Doypack System will be definitly your great option. So why hesitate, just contact US for more details~