What is vertical form fill seal packaging machine

Vertical form fill seal packaging filling machine, also commonly referred to simply as VFFS, is the most common packaging machine, and widely use in variety of industry, like the food industry, daily chemicals industry, puffed food and other industries.

It can be used as a part of the whole production line, matching with different front-end production equipment and the weighing equipment, then constitutes a complete automatic production line. It can also be used alone to complete the bag making and packaging for your products required to be packed. Very flexible to use.

How is the vertical form fill seal packaging machine be constructed

As the name “Vertical Form Fill Seal” suggests, this machine working flow is also obvious. The machine structure is Vertical Type. It first help to FORM bags from film rolls material. Then, the bag will be filled with products that needs to packed, and finally get sealed. A finished bag is done.

On the one hand, the Vertical Form Fill Seal machine is convenient to split big batch of product into small independent bags, better for its long-term storage, on the other hand, it also good for long-distance transportation and small-lot retailing sales.

With the rapid development technology, modern manufacturers have more diversified and personalized packaging style. So in addition to above advantages, they consider more and more about the “outlook” bag effect. As this will have a crucial impact on their brand image. Ultimately, it affects consumers’ desire to buy, which in turn affects the profitability of enterprises.

In order to meet manufacturers’ above needs , Packway packaging machines have been continuously upgrading and optimizing their own systems and structures. Now it can be configured in different ways to meet the requirements of various bag types, such as ordinary pillow back-sealed bags, gusseted bags, and block bottom bags.Also can do different bag size to fit different bag capacity request.

What are the advantages of the vertical form fill seal(VFFS) packaging machine

In the past, many great design bags like stand-up pouch, zipper pouch has to made as preform bags, it’s not exclusive to preform bags anymore. More and more of that can be realized by VFFS machine. A perfect bag effect is no longer difficult job for the VFFS machine. More surprises will come in near future.

You can be easily find VFFS bags in the supermarket. It still occupy the majority of the market share because of its Low input-output ratio. The most common example may be chips bags, as well as various snacks, also they can be used with various liquids, powders, and other dry goods in variety of settings.

What about the packaging speed of the vertical form fill seal packaging machine

Our vertical machine is very mature technology, the most ordinary standard machine has no problem to run with speed 40~60 packs per minute. And if upgrade to double servo structure, means film pulling by servo motor, and horizontal sealing control by servo motor, the double servo structure can make whole system run even faster, reach 70~100 packs a minute. In addition, the packaging raw material of the bag is film roll making bag, even you print your own design and logo on it, the total cost of each bag is significantly lower than that of prefabricated bags.

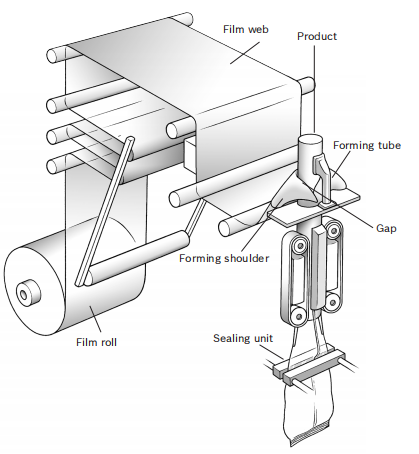

Here let’s have a quick look at the basic work flow and functions of the machine.

The working process of the vertical form fill seal packaging machine

Forming a bag by Bag Former

The first step in the operation of the machine is to feed the film roll into the bag former.

There is a film loading mechanism on the backside of the machine, which is specially designed to install the film roll and release the tension. You can adopt transparent blank film, or printing film roll with your own design on it, printing film should add color mark to ensure each bag has complete design on each bag. The vertical Packing Machine can accept both.

The bag length of transparent film roll can be set on the touch screen; the length of the printed film is precisely cut by identifying the color mark.

How does the roll film turn into the bag shape you want?

When the machine feeds the film through the film mechanism and wear through the bag former to the forming tube, it forms a certain shape of bag

For each type of bag style, the bag former design is different; Even if it’s same bag style, the size of the forming tube determines the bag width. That is, when you want to change the bag width of the bag, you need to quickly replace another size of bag former.

The conclusion is:

One bag style, one bag former design

One bag width, one unique bag former;

But the bag length can be changed through the screen,without replace spare parts.

So you must confirm your bag type and bag width first before we can design a suitable bag former for you.

Dosing & Filling Material into bag

When the bag is formed, the bottom bag and vertical have been sealed, and the top of the bag is open.

The next step is dosing and filling. The three most commonly used dosing device are:

Auger Filler for dosing powder

Combination scale/linear scale for granular/block materials;

The metering device is generally installed directly above the host, so that after measurement, the material can fill directly into the bag through inner forming tube;

The two machines are electronically synchronized, so to ensure once the bag is ready, the product will be filled automatically.

Top Sealing and Finished bag output

Final Step, the top of the bag will be sealed automatically right after a certain weight of product completely filling, the sealing step will complete the top seal of the first bag and bottom seal of next bag at the same time, and then cut it off. Till then, it complete the whole process of making a bag , repeat that process.

Auxiliary equipment may required

According to customers’ actual requirements, the machine can also equipped with a coding printer, easy tearing device, hanging hole on top, etc.

These bags will finally be collected and packing into cartons, shipped directly to stores for retail selling and ultimately to the user.

Packway company can help you design and manufacture a full series of vertical packaging machines,

Contact us to get a quote anytime.